Reinforced concrete piping

DESCRIPTION AND USES

The HM reinforced concrete pipes by PREFABRICADOS ALBERDI S.A. is intended, principally, for underground pipelines, road drainage, black water or sanitation, rainwater and surface water by gravity or, occasionally, pressurised. Given their inner steel reinforcement, they are ideal for bearing considerable loads generated by road traffic or significant coverings of soil.

The HM reinforced concrete pipes by PREFABRICADOS ALBERDI S.A. is intended, principally, for underground pipelines, road drainage, black water or sanitation, rainwater and surface water by gravity or, occasionally, pressurised. Given their inner steel reinforcement, they are ideal for bearing considerable loads generated by road traffic or significant coverings of soil.

They can be classified according to their geometric shape and their manufacturing method. On one hand, there are the “bell and spigot” type pipes manufactured by radial compression (hereafter TEC) and “tongue and groove” or “halved joint” type pipes made by vibrocompression (hereafter TEM).

At the same time, the European Directive 89/106/CE of Royal Decree 1630/1192 establishes that reinforced concrete pipes must have the CE marking complying with the provisions of the current standard in force, UNE EN 1916:2003. This is why at PREFABRICADOS ALBERDI S.A. we mark all our pipes accordingly.

TECHNICAL DATA

NAME AND REGULATIONS: REINFORCED CONCRETE PIPES

RESISTANCE CLASS

Ff: Cracking load (KN/m2)

Fn: Breaking load (KN/m2)

ACCORDING TO UNE EN 1916

| CLASS 60 | CLASS 90 | CLASS 135 | CLASS 180 | |

|---|---|---|---|---|

| Ff | 40 | 60 | 90 | 120 |

| Fn | 60 | 90 | 135 | 180 |

ACCORDING TO ASTM C76 M

| CLASS I | CLASS II | CLASS III | CLASS IV | CLASS V | |

|---|---|---|---|---|---|

| Ff | 40 | 50 | 65 | 100 | 140 |

| Fn | 60 | 75 | 100 | 150 | 175 |

Reinforced piping by radial compression

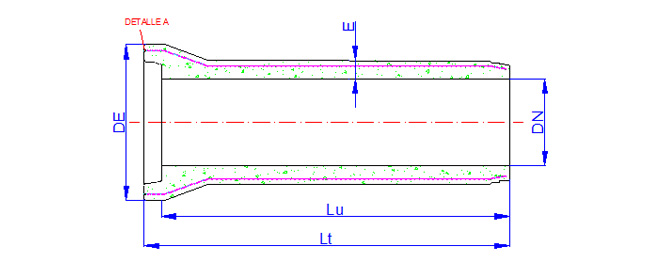

TEC PIPE

| DN (mm) | DE (mm) | E (mm) | LU (mm) | WEIGHT (kg/ml) |

|---|---|---|---|---|

| 300 | 540 | 55 | 2,400 | 175 |

| 400 | 680 | 62.5 | 2,400 | 271 |

| 500 | 780 | 70 | 2,400 | 355 |

| 600 | 910 | 76.5 | 2,400 | 492 |

| 700 | 1,040 | 85 | 2,400 | 585 |

| 800 | 1,150 | 95 | 2,400 | 727 |

| 1,000 | 1,405 | 110 | 2,400 | 1,055 |

| 1,200 | 1,675 | 125 | 2,400 | 1,460 |

| 1,400 | 1,900 | 145 | 2,400 | 1,840 |

| 1,500 | 1,900 | 150 | 2,400 | 2,050 |

| 1,600 | 2,240 | 160 | 2,400 | 2,640 |

| 1,800 | 2,295 | 180 | 2,400 | 2,845 |

Reinforced piping by vibrocompression

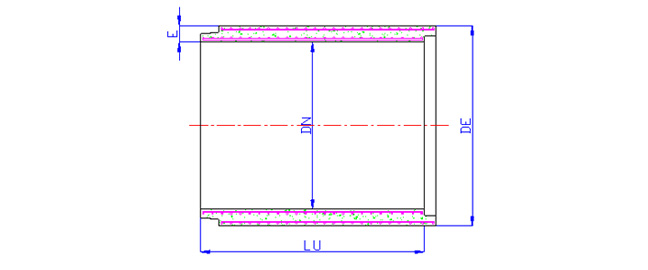

TEM PIPE

| DN (mm) | DE (mm) | E (mm) | LU (mm) | WEIGHT (kg/ml) |

|---|---|---|---|---|

| 1,600 | 1,940 | 170 | 2,400 | 175 |

| 1,800 | 2,180 | 190 | 2,400 | 3,010 |

| 2,000 | 2,400 | 200 | 2,400 | 3,350 |

| 2,500 | 3,000 | 250 | 2,400 | 5,250 |

| 3,000 | 3,600 | 300 | 2,400 | 7,775 |

QUALITY CONTROL

- Tightness test using the air leakage test on 100% of the pipes manufactured the previous day (up to Ø1200 included).

- If the pipes are manufactured in batches for a particular client order (subject to a surcharge), in addition to the aforementioned test, the following quality control will be performed:

- Compression resistance of specimens of fresh concrete

- Analysis of the consistency of fresh concrete

- Alkalinity and water absorption

- Layout of the reinforcement

- Mechanical resistance: breakage test of the three edges

- Hydrostatic tests (up to Ø1200 included).

- Tightness tests on the gasket

PHOTO GALLERY

Utilizamos cookies propias y de terceros, para realizar el análisis de la navegación de los usuarios. Si continúas navegando, consideramos que aceptas su uso.

Puedes cambiar la configuración u obtener más información aqui.

Arriandi auzoa, 1

48215 Iurreta - Biscaye (Espagne)

Tél. : +34 94... voir téléphone

Fax : +34 94... voir fax

Prefabricados Alberdi - Copyright 2012 | Avertissement légal | Protection des données | Plan du site | Cookies

Site web conçu par

et développé par DMacroweb